Choice of materials includes, but is not limited to, Super Duplex and various Inconel alloys for the metal part and FEPM and FFKM (i.e. Viton™ Extreme™/ETP 600S, Kalrez®, Simriz®, Chemraz®, Tecnoflon® PFR FFKM) for the elastomer part.

Bonded seals, also known as Dowty® seals, are commonly only available in structural steel or stainless steel, with elastomer part in either NBR or FKM Type 1 (often referred to as Viton®). Structural steel and NBR have limitations both in temperature resistance, typically up to 100°C, and chemical compatibility.

A combination of stainless steel and FKM offers a broader chemical compatibility, but incompatible with harsh media such as strong acids or alkaline media at elevated temperatures. Temperature typically between -20°C to +200°C, depending on the media. For more demanding applications stainless steel/FKM is simply not up for the job.

- With the right combination of metal part and elastomer we can provide resistance to virtually any chemical/fluid in temperatures ranging from -40° to +320°C.

- Typically the metal ring can be supplied in Super Duplex, various Inconel alloys or other high-end metals in terms of strength and corrosion resistance.

- The elastomer part is typically offered in Viton® Extreme, low-temp FFKM or other high-end elastomers suitable for the given application.

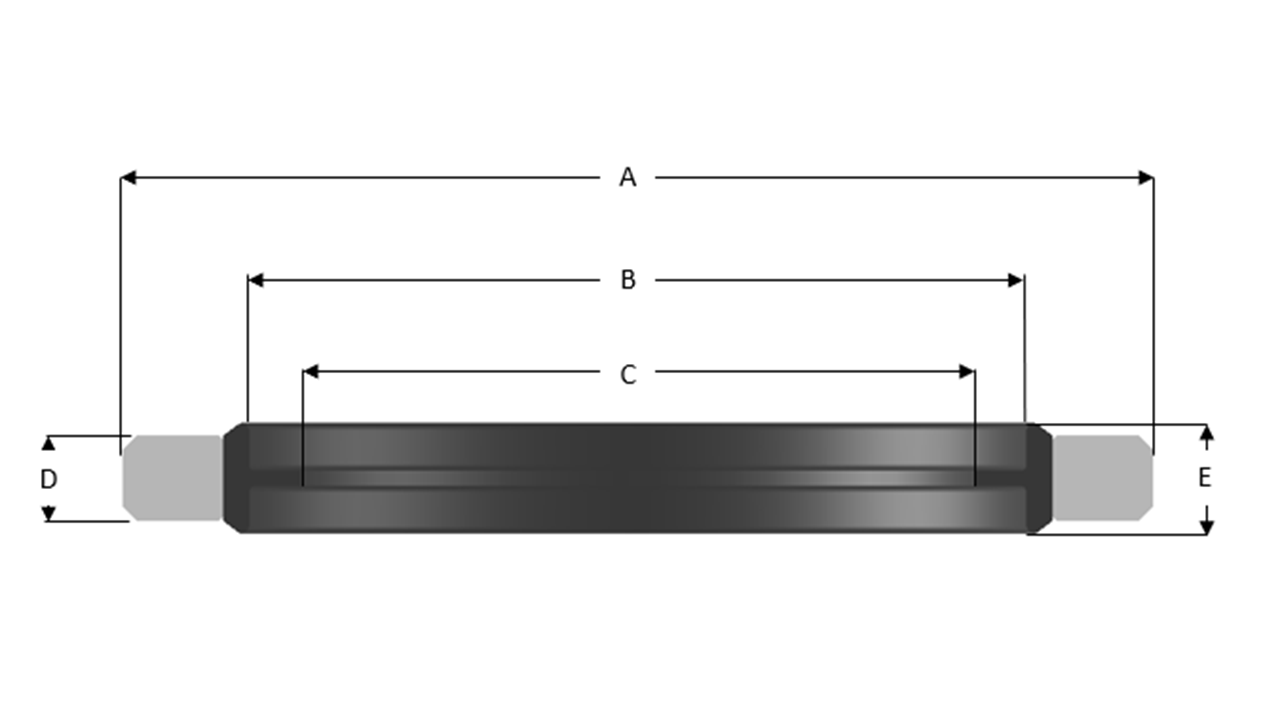

- Our bonded seals are offered as self-centring which is a huge advantage during assembly, ensuring that the seal maintains a concentric position.

- Standard sizes in both inches and millimeters are offered, and even non-standard sizes are available with short lead-time