Sealing solutions for hydraulic equipment

Hydraulic seals are crucial components used in hydraulic systems to prevent fluid leakage, contain pressure, and maintain the integrity of the hydraulic system. These seals are designed to work in dynamic, high-pressure environments where hydraulic fluid is used to generate mechanical force and motion.

Read more about sealing profiles, materials and system design

We have specialized in machining of seals, which provides unsurpassed flexibility in terms of delivery time, material choice, shape, geometry, dimension and tolerance. The seals can be adapted to your specific needs - rapidly! There are various types of hydraulic seals, each designed for specific applications. Common types include O-rings, piston seals, rod seals, wiper seals, combined in a system with guide rings and backup-rings.

Wipers

The function of a wiper is to prevent particles from entering the components in a hydraulic or pneumatic circuit, cylinders or valves. This helps prevent contamination of the media which will damage the seals and metal surfaces

Piston seals

The main function of a piston seal is to maintain sealing between the piston and cylinder bore, ensuring that energy in the media builds up pressure inside the cylinder and transforms this to mechanical force through the cylinder rod. They are typically made of materials like polyurethane or rubber and come in various designs.

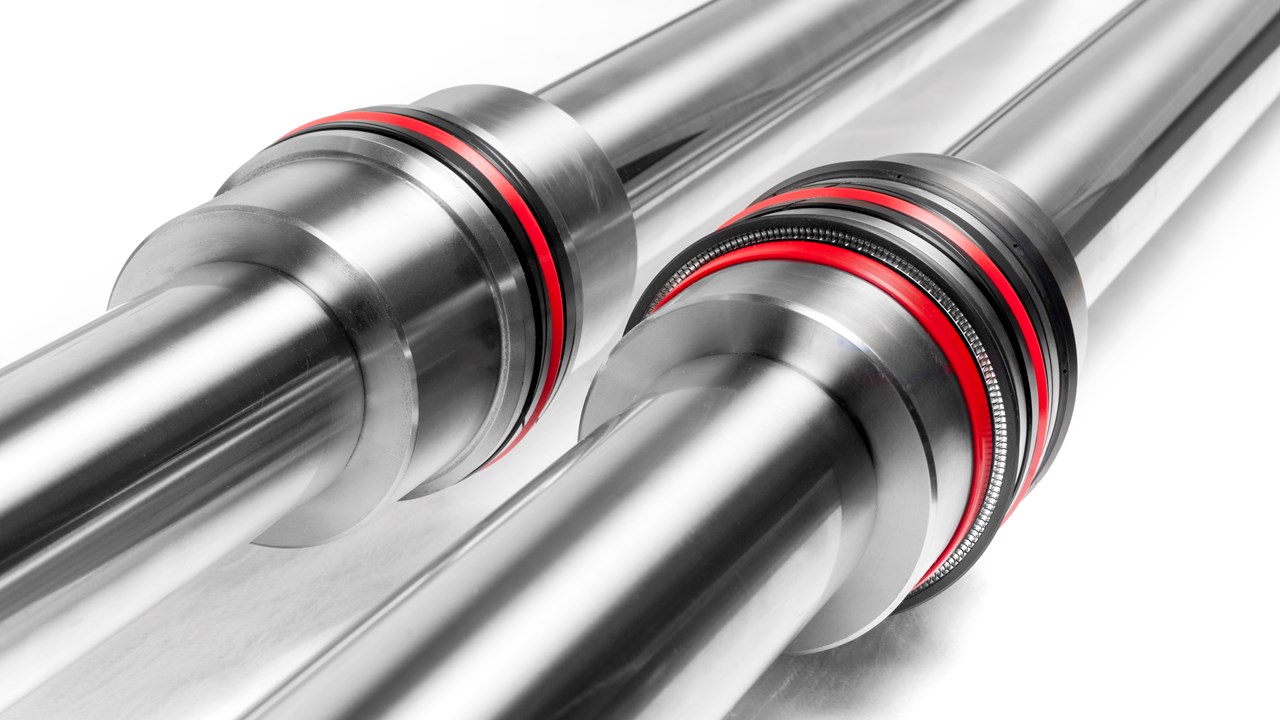

Rod seals

The major function of the rod seal is to prevent the media from leaking trough the rod gland when the cylinder is pressurized. In order to work properly a small lubrication film should pass under the seal, and return (back-pumping) to the cylinder when the rod is retracting. Depending on the application one or two (sometimes more) rod seals are used for maximum sealability. The primary rod seal must withstand the system pressure.

Guide rings

The function of guide rings is to prevent metallic contact between surfaces of moving parts. In order to obtain correct positioning the guide rings must have capability to withstand radial loads acting on piston and rod.made out of fabric reinforced resin and various thermoplastics have replaced the use of metallic guides. This has resulted in a considerably longer service life for hydraulic cylinders.

O-rings

O-rings are among the most common types of hydraulic seals. They are simple, ring-shaped seals typically made of rubber or elastomeric materials. O-rings are used to seal the connection points of hydraulic components, such as fittings and connections, to prevent fluid leakage.

Backup rings

O-rings are often used as static sealing elements in hydraulic systems. However, they tend to extrude into the radial gap between the steel parts already at low pressures and are thereby destroyed. A possible solution is to combine O-rings with backup rings.

However, there are many solutions available for a simple O-ring groove and different solutions can affect many aspects of the application and its functionality.